Describes how to take a set of Gerber files representing a multi-layer PCB and import them into SolidWorks. The import includes a function that generates the. Working with circuit boards/gerber files I have designed a custom circuit board that I now want to model a case for, is there a way I can import the gerber files into Fusion to work with? Will Fusion create a model based on those files. Import Gerber, and rout (Excellon etc.), DPF, ODB, HPGL: Import CAD and CAM aperture lists: Print: Measure sizes and distances: Export Gerber, DPF, NC drill: Save jobs with all layer data in one file: Setup templates for easy loading of multiple layers: Add and remove elements, insert text, and chamfers: Rotate, mirrror, scale and swell. Importing Gerber/DXF from PCB into SolidWorks As the design of PCB's becomes more complex, the need to do 3D modeling of a printed circuit board also becomes more important. Many PCB design tools have an interface to SolidWorks via the IDF file.

For clients using Altium Designer, this guide will help you configure and output Gerber files as well as NC Drill files in RS274X format. It is assumed that you have finished designing your schematic as well as PCB layout. You should have both a .SchDoc file (schematic) and a .PcbDoc file (PCB layout) at this stage.Generating Gerber Files

Step 1: First, navigate to “File” tab at the top left corner of the program window. Next select “Fabrication Outputs” and in that drop-down menu select “Gerber Files”.Step 2: Once Gerber Files is selected the window below will appear which will allow you to specify the units and number digits before or after the decimal point.

Step 3: Next, using the tabs at the top of the window, navigate to the “Layers” tab. This will allow you to select which layers will be used for the output gerber files. If you are unsure which layers will be used, select the “Plot Layers” tab in the bottom left of the window and click “All ON” so it is highlighted. This will select all possible layers in the project for output.

Step 4: Afterward, using the tabs at the top of the window again, navigate to the “Apertures” tab. While in this window, ensure that the “Embedded Apertures (RS274X)” box is checked. The rest of the window can be left in its default settings.

Step 5: Finally, once again using the tabs at the top of the window, navigate to the “Advanced” tab. The settings in this window can be left default unless your design has special requirements. When you are finished press “Ok” in the bottom right of the window which will begin the output process for your gerber files.

Step 6: Once your main layer files are completed you need to output your NC Drill files. When fabricating your PCBs, these files indicate the size and placement of the holes which will be drilled for vias, mounting points, etc. First, return to the top left of the program and select “File”. In the drop-down menu select “Fabrication Outputs” and then “NC Drill Files”.

Step 7: The previous step will open up the NC Drill File setup window. This will allow you to specific units and the number of digits before or after the decimal. This window can be left default unless your project requires specific parameters.

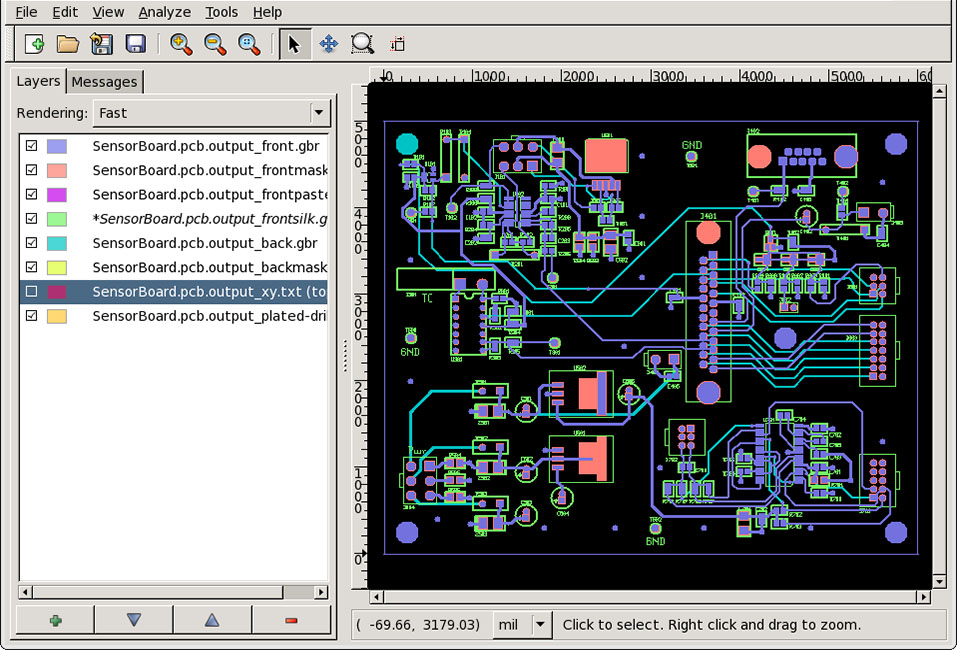

Step 8: Finally, if you have saved all your files in one location you should have a similar number of files as shown in the picture below. Remember when submitting your files, it is best to compress the files in a .zip file to ensure they remain grouped together.

If you still find any steps involved in this process, please do not hesitate to contact a member of the Bittele Electronics sales team by sending an email to sales@7pcb.com, or calling our Toronto office at 1-416-800-7540. We are happy to help with any questions or concerns you may have and we look forward to working with you.

Solidworks Pcb Cost

Related Articles:Search articles:

Library Management Tools

Easily create and manage schematic, footprint, and integrated libraries directly within SOLIDWORKS PCB. There are a variety of tools to create schematic symbols and PCB footprints including an IPC compliant footprint wizard.

SOLIDWORKS 3D Collaboration

Seamlessly collaborate ECAD designs between electrical and mechanical teams. There’s no exporting or importing files - all communication and 3D board information is communicated through the built-in SOLIDWORKS PCB Connector. This connector ensures that the PCB is going to fit in an enclosure, and if not, it can be modified and pushed back to the electrical designer. The connector also allows for silkscreen and copper to be represented in 3D.

SOLIDWORKS PDM Integration

Solidworks Pcb Services

SOLIDWORKS PCB can be integrated with SOLIDWORKS PDM to securely manage all the files that are inherently required for an ECAD design, including revision control. Projects can begin inside of PDM and have part numbers generated automatically.

Schematic Layout

Powerful and intuitive schematic layout tools allow designers to create the intelligence behind the printed circuit board with ease. Build circuits by drag and dropping components from the library and connect components with intelligent wiring tools. Automatically annotate components formulaically to ensure unique component identifiers. Designers can also run spice simulations to confirm that the circuit is set up correctly.

Supplier Links

How To Open Gerber Files

When designing a printed circuit board, it’s essential to have an up to date Bill of Materials. SOLIDWORKS PCB can create and manage supplier links that connect to live supplier databases, showing datasheets, stock availability, and cost of real-life components.

PCB Layout

Create printed circuit boards quickly and easily by importing nets and components from the schematic. Interactively route traces from a single or multiple pads at the same time, generate board stackups that contain up to 32 mechanical and single layers, and create customized design rules to meet requirements.